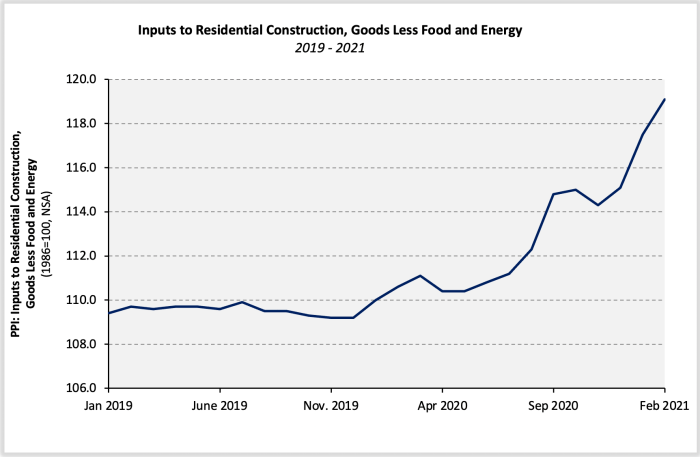

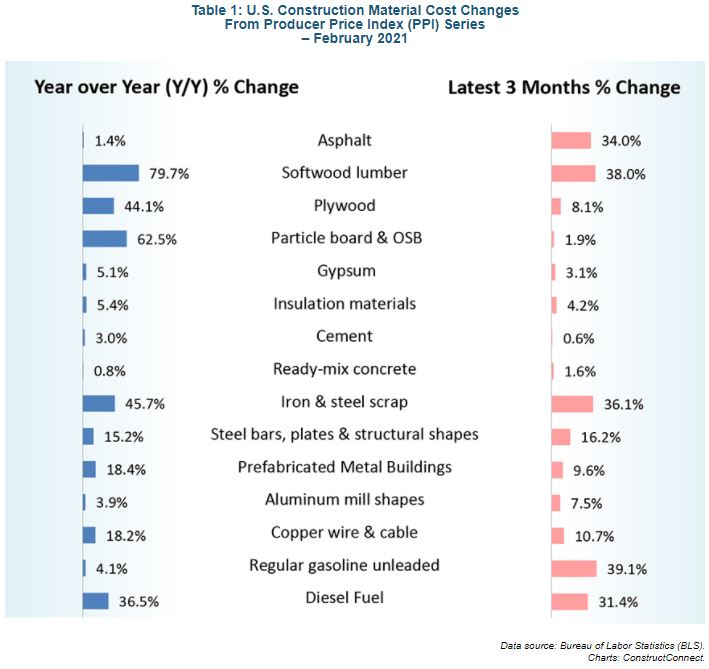

Whether you’re a general contractor or architect, or a homeowner with a construction project in the works or on the horizon, you’ve been watching the steady rise in material costs over the past year with concern. And now that those same material costs are shooting up wildly in 2021, the alarm bells are sounding. These charts showing the recent pricing spikes for lumber, hardware, plasters, finishes, and specialty materials look like Mr. Toad’s Wild Ride.

There are theories for why prices have gone haywire: the long-term effects of Covid have caused supply shortages, producers are trying to make up for the lost profits of the last year, U.S. trade policy has hit construction especially hard, a spike in construction activity has wiped out inventory, or maybe suppliers are simply charging more across the board, because they can. (For an interesting discussion of today’s pricing phenomenon, listen to the NAHB podcast, “Podcast: Mill Owner Discusses Lumber Crisis, Possible Solutions.”)

But far be it from us to offer the definitive reasons for the economic ins and outs of the cost-crunch. What we’re all most immediately concerned with is the pain we’re feeling, whatever the cause, and what we can do about it.

Prices Good for 24 Hours!

Just a few days ago, we received an urgent email from one of our lumber suppliers that opened with: “These prices good for one day only!”

Seriously? We expect to see such urgent come-ons from a local grocery story or a mattress warehouse or an electronics outlet, but from a lumber supplier for the construction industry whose orders start in the tens of thousands of dollars? As a construction company that builds complex and sizable projects: home theaters, recording studios, safe rooms, and luxury remodels, we typically order materials only after a laborious process of cost-and-materials sourcing, detailed bid preparation, negotiation, and finally a contract signing. How can we work through that process in any sane way when the pricing we obtain in order to prepare the bid vanishes into thin air even before our initial calculations are computed?

How To Slow Down the Pricing Roller Coaster Ride

Here are some of the things that we do to cope with the crazy roller coaster ride in materials costs. To the extent possible, we will buy some materials at contract, to lock in those costs. We’ll commit to some other costs, regardless of price fluctuations in the market. We build into our contracts a reasonable escalation clause, providing that should prices increase for certain materials before the time that we can order them, we’ll generate a cost-increase change order. If lower-cost alternate materials are available, we will offer options for substitutions. We bulk buy and store some commonly used materials. And we work diligently to build and maintain long-standing, positive supplier relationships so that our suppliers are highly motivated to make deals with us that will keep our business flowing.

Trust is Worth More Than Pricing

Then there’s the big issue of reputation and trust; a matter not so much of what you can do now, but what you have done already. We follow a two-level bidding process, and have done so for a long time, which ensures that all questions of materials and specifications are answered down to the last detail before a final, detailed bid is prepared. And we rigorously maintain open communication and flow of information from the first arrival on site through the final day of sweep-up when a build is finished.

This devotion to transparency, meticulous planning, unrelenting forward movement on our builds, and consistent communication are the cornerstones of our operation. We build trust while we build structures, and that pays off in tough times.