Homes featuring the latest look in architectural design – hard surfaces, minimal or no window treatments, and wide-open spaces – often present the most troublesome acoustical challenges. All those stark expanses of wall, floor, and ceiling, and the huge volume of unimpeded air space will naturally reflect, duplicate, and amplify sound. While an open, streamlined visual design can conjure peace and serenity, the actual use of the space can deliver chaos to the ear.

Of course, public spaces built with huge walls, high ceilings, and generous room proportions present the same challenges which are then exacerbated by an additional feature; lots of people. In a conference space, mall, or restaurant, the many human voices alone can create a deafening din, much less the noise of chairs being scooted, and plates, forks, and glasses being used.

Acoustic Plaster Cuts Sound Without Interfering with Design

Acoustical plaster can be a perfect solution in these situations, maintaining the sleek, modern lines of the space with what appears to be a hard surface. But the material actually is made up of not just the specialty plaster, but additional components hiding behind the visible surface that dampen sound. The secret is in the materials used to make the plaster and the multilayered specially engineered construction at installation.

What Is Acoustic Plaster, Exactly?

Acoustic plaster systems are microscopically porous surfaces applied onto a mineral wool panel. The wool panel is designed to capture high- and low-frequency sound energy that collides with the panel’s surface and convert it into heat energy.

High-frequency sound waves penetrate the acoustically transparent plaster surface and then are trapped by the mineral wool backing behind the plaster. The wool backing, in turn, converts the sound energy into heat energy.

Low-frequency sound waves, on the other hand, hit the plaster surface and cause a “diaphragmatic vibration.” In other words, the plaster flexes microscopically in response to the sound waves and through the flexing action, transfers the sound energy to the wool backing that again transforms the energy into heat.

In all, 80 to 85% of the sound energy that hits the acoustic plaster surface is absorbed rather than reflected, reducing noise significantly.

Acoustic Plaster Isn’t Just Plaster

An acoustic plaster installation consists of a precoated mineral wool layer to which layers of adhesive, prefill, base coat, and topcoat, also known as finish coat, are applied onsite. The process requires precision in measuring, cutting, and applying the many coats necessary to create an acoustic plaster installation.

Not Everyone Can Install Acoustic Plaster

Our expert team of installers have been trained and certified to perform this specialty work. The materials that we use are certified by third-party lab testing to deliver the highest sound absorption available.

Acoustic Plaster Is Eminently Customizable

The cool thing about acoustic plaster is that it comes in a multitude of colors and finishes so it can integrate beautifully with the design of any space. And unlike any other sort of sound-damping installation or structure, acoustic plaster follows the exact size, shape, and contour of the wall or ceiling being treated, keeping the initial design of the space intact.

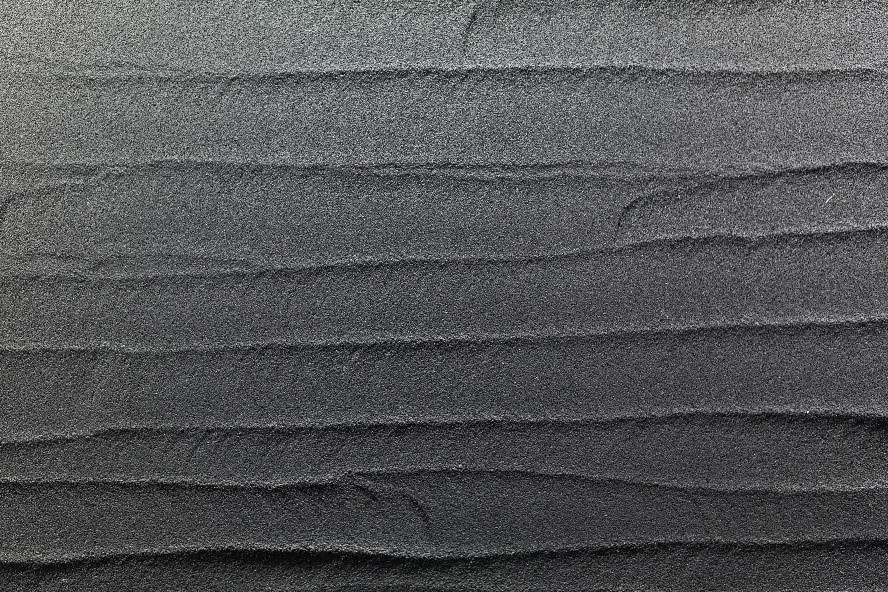

Take a look at these samples of acoustic plaster finishes, and the dramatic wall and ceiling contours that have been created using acoustic plaster.